Over the past few weeks I've been in discussions with

The National Museum of Computing regarding helping out with the restoration of their recently donated Armdroid 1, and guess what....

I've enrolled as a member of the volunteering staff, and will shortly start work on my first restoration project for the museum. Looking at the overall condition of this, I really can't imagine this will take very long....

Sure, its dusty, a little bit rusty in places, but on the whole, the mechanics look to be in amazingly good condition.

The reduction gears, do however appear to have suffered from those hair-line fractures, which I've previously talked about as a fairly common problem, but, there really is nothing here that cannot be replaced or repaired.

That said, I'll be stripping down the entire mechanics, possibly separating the bearing housing, ensure everything is cleaned and lubricated before rebuilding.

We'll need to re-string with new Kevlar, and as I have spare timing belts, we'll change these too.

Mind you, I have no idea what condition the electronics are in, but the same approach to testing this circuit will be employed as before.

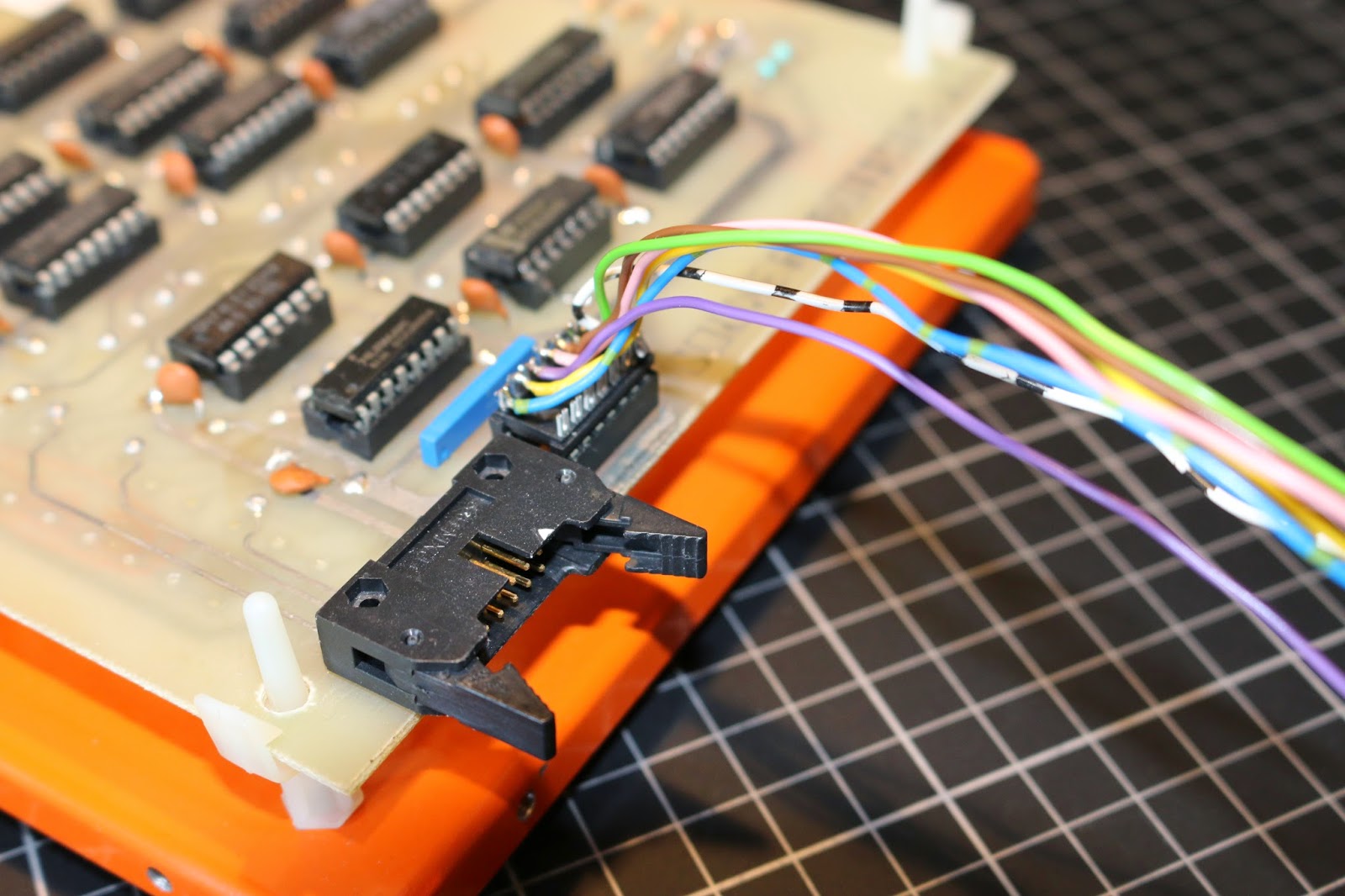

Peeking inside, I could identify an Issue 4 driver board, which is exactly the same revision as my production board, but with all the wires hanging outside.... yeah...well... who knows at this stage !

It's really nice to have an original power supply, I've never seen one before, and I'm looking forward to seeing if this works. The PAT test (UK electrical safety) sticker is dated 1999, so possibly its been a while since last use.

The intention is to put this on interactive display in the museum - I've always liked exhibits in museums with buttons to press, making things work.... and most likely, this will use a Raspberry Pi or Arduino as the controller behind the scenes.

My new patient close-up :

I intend to draw-up schematics of this power supply as I don't believe these are published anywhere on the internet. I have seen circuit diagrams for the original prototype power supply, but they do differ in output voltages.

I'm not intending to update the Blog with every step of this rebuild, but if anything interesting is discovered, or different to what has been previously covered, then I'll certainly make an update.

Readers of the Blog will know I'm currently developing an updated version of LEARN for Windows, whilst this activity is still taking place, it is likely to be delayed a little.

Of course, one of the benefits of volunteering your services, is that you get to play with lots of nice kit, and this could possibly be my next "big" project.... Take a look at this beast.....

It's a manipulator arm from a submersible Remotely Operated Vehicle (

ROV), previously used in the North Sea from the Oil & Gas Industry.

We believe this was would have been used for Inspection Repair Maintenance (IRM) work at depths of around 50 - 300 meters.

It runs on Hydraulics operated from electromechanical values, with control signals feeding down an umbilical cable from the surface vessel. The operators controlling the ROV and ARM would be aboard this vessel.

|

| Gripper close up |

With a gripping force around 1000 lb (454Kg), this is somewhat stronger than the mere 5 lbs the Armdroid is good for! I'd say, keep your fingers well away!

|

| Base Arm Cylinder was removed for packaging |

In the photograph above you can clearly see the black hydraulic lines with grey sheathing to group them. The transparent brown sheath caries multiple signal wires, which we believe run from positional encoders, and possibly other solid-state sensors.

The signal cables and hydraulics feed into the value assembly. There are 14 hydraulic actuator lines in total.

|

| Hydraulic Valves |

We believe a hydraulic feed from the ROV supplies these valves - there is no separate hydraulic pump. You can also make out the pressure monitor inside opposite the hydraulic feed lines on the right.

The large blue cable contains multicore signals and feed into this, which appears to be some kind of transformer / interface unit that would be strapped somewhere to the ROV structure.

The connector on the left is labelled 110v which we believe carries both power and serial data.

Everything about this arm is unbelievably heavy, making it somewhat difficult to inspect everything. Luckily, Daniel Bull was around to help lift things.

We've started researching the manufacturer, history, and have reason to believe the software may have been developed in Milton Keynes.

Although we're missing a hydraulic pump, we're wondering if it's actually possible to resurrect this thing back to life.... I don't claim to know anything about hydraulics, but we'll be reaching out to experts in the industry. Crazy... yep, I'm sure we'll have lots of fun in the process !

|

| One of the operator's control panels |

Although damaged, the controller reflects each degree of freedom of the manipulator. There is certainly a possibility we could re-purpose this as an Armdroid controller.

I'm actually wondering.... Has anybody out there interfaced a Raspberry Pi to an ROV manipulator arm, or would that be a first ?

It might be possible to interface the valve assembly directly to the GPIO with appropriate drivers and buffers. This takes the high-voltage out of the equation, and saves us figuring out that serial protocol....

Of course, if you recognize the above hardware or have experience of ROVs - operating or engineering please do drop me a message.

If you want to find out more, be sure to follow on

Goggle+ as that's where all my adventures at TNMOC will be posted - I'm trying to keep this an Armdroid blog after all. Additional photographs of this project will also be added here.