Despite the mayhem, I managed to spend a couple of hours cleaning the upper arm assemblies.

I did this cleaning whilst sitting in front of the TV and was talking to Yulia about the restoration project... she especially enjoyed me telling her this........ not !

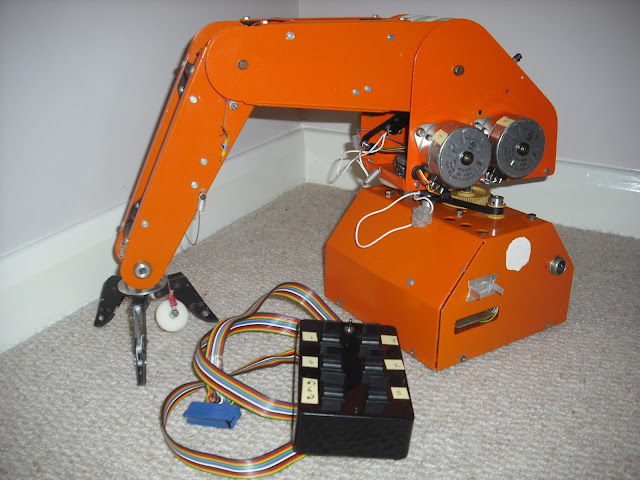

I took these photographs of the upper arm with my FUJIFILM camera on the coffee table, almost look professional don't they?

Certainly scrubs up well... I cleaned every tooth of the reduction gearing, and thankfully no damage or concerns to note.

Some of the finger joint pins and circlips have rusted, these we will probably be replaced, but with a little help from WD-40, they eventually freed which will be good enough for starters:

|

| Finger assembly |

Apart from a few scratches on the metal work, the upper arm is actually in pretty good condition, and more importantly is mechanically sound.

The gripper is attached by three bolts and comes off easily:

|

| Gripper and Differential Gearing assemblies |

The marketing literature actually mentioned the gripper could be replaced by a pneumatic sucker for handling board or sheet, or electromagnetic manipulator, etc. Perhaps a project sometime for the future ?

The strings will be completely replaced, and I'll be restringing this in a couple of weeks time.

I noticed a bodge with these control strings and how they have been attached to the tension springs:

The blue prints show cable clamps on both sides - instead crimp connectors have been used here. An example of a cable clamp is pictured above right.

Trying to adjust cable length or tension will certainly be problematic with this current arraignment.

These crimped connections shown are as designed:

|

| Large hand sheave pulley |

|

| Crimped eyelet supporting Fore Arm |

The cable clamps are 6 x 6mm and contain an M3 grub screw to lock the string in place.

Whilst we continue to get the house back in order, I will give consideration what I'll be doing about these missing clamps.

I expect the project will resume in a couple of weeks - and as one dodgy actor once said... "I'll be back!"